|

Improve Performance

and Extend Tool Life With Air Preparation

|

|

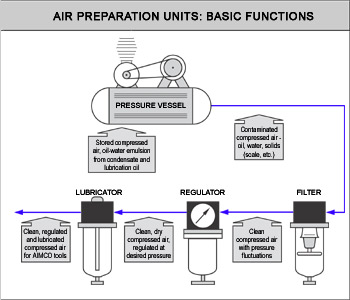

The

supply of clean, dry air is essential to the operation

of pneumatic powered tools. Use only clean

filtered air for longer tool life. Provide proper

airflow (CFM) and regulate air pressure (PSI) for

optimum performance.

|

|

AIR CONTAMINATION SHORTENS TOOL LIFE |

- Moisture

- Dirt

- Rust particles

- Decomposing compressor oil

|

A filter placed in the air

line before the tool and close to the application can remove particles and

moisture from compressed air before it reaches the tool. Filters and

proper maintenance practices can help protect and extend the life of your

valuable tools.

|

|

AIR PRESSURE AFFECTS TOOL PERFORMANCE |

Fluctuation in air pressure (PSI) may be

caused by:

- Compressor performance

- Temperature changes

- System demands

- Predictable pressure loss through hose

- Distance from source

|

An adjustable regulator with pressure gauge

allows PSI to be set and monitored for each tool application. Locate

the regulator before the tool and close to the application. Regulators

keep a constant air supply on the tool side, despite fluctuations in

incoming air pressure. Appropriate air volume and PSI allow the tool

to operate smoothly and at optimum performance, maximizing productivity.

Torque control tools will operate with greater repeatability when they

receive consistent air pressure.

|

|

LUBRICATION IS CRITICAL FOR MOST MECHANICAL

COMPONENTS |

- Lubrication reduces wear

- Extends tool life

- Reduces repair cost

- Reduces maintenance time

|

A mist lubricator installed between the filter

and not more than 15 feet from the tool will provide ample lubrication for

most pneumatic tools. Set lubrication to the lowest setting for best

results.

|

|

AIMCO AIR PREPARATION UNITS |

AIMCO's modular air preparation units are

offered in a variety of configurations, inlet sizes, and capacities to suit

most applications. Combination units are available which include the

filter, regulator and lubricator packaged together for simple installation.

Each item is also available as a separate item.

|

- Complete Filter, Regulator,

Lubricator Units: Three-piece modular units feature 30-micron filter

with semi-auto drain, regulator with gauge, and oil mist lubricator.

All units include mounting bracket and polycarbonate bowl.

- Complete Compact FRL Stack Units: Space

saving units include combination filter/regulator with gauge and

lubricator in a more compact size. Features 30-micron filter with

semi-auto drain. All units include mounting bracket and

polycarbonate bowl.

- Compact filter/Regulator Stack Units:

Combination units for use when additional lubrication is not needed.

Includes 30-micron filter, polycarbonate bowl and semi-auto drain.

Order mounting bracket and gauge separately.

|

|

|

To determine unit size for application, you

will need to know:

- Total air flow (CFM) required for

application

- Size of incoming air line

- Size of air line required by tool

- Air supply pressure (PSI)

- Allowable pressure drop

- If the application requires lubrication

- If the overall system has the required

capacity

|

| |